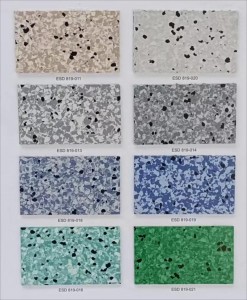

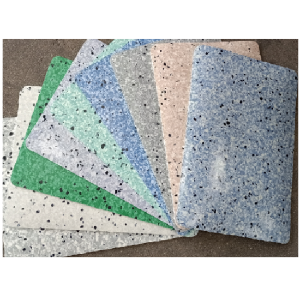

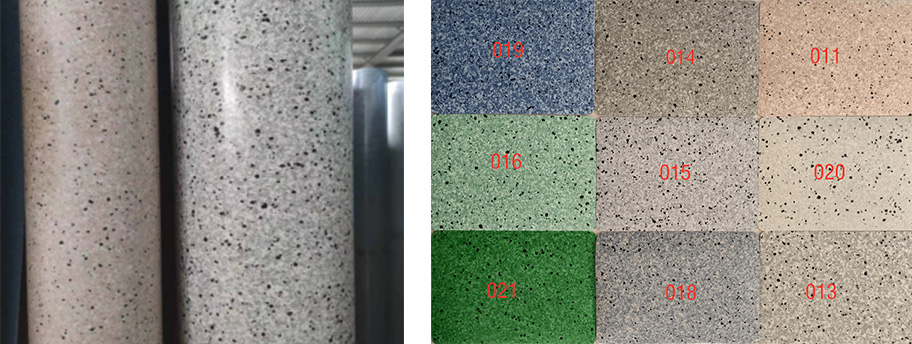

1.Anti-static homogeneous vinyl dissipative floor has permanent anti-static function because it uses conductive static network formed at the interface of plastic particles along with the common homogeneous vinyl floor performance such as waterproof,flame retardant,wear resistant,sound absorption,chemical resistance etc,when it is grounded or connected to any lower potential point, enables the electric charge to be dissipated. It is characterized by a resistance between 10 2nd power and 10 9th power ohm.

2.Characteristic of Anti-static homogeneous vinyl

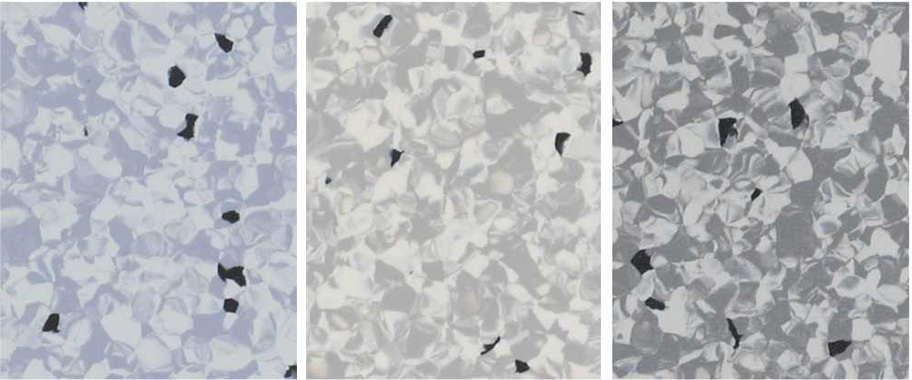

Homogeneous compact

Non directional pattern

Carbon granules connecting surface to conductive backing.

Black conductive backing makes installation less expense,technically safe

Excellent electrical values for meeting customers' ESD needs.

6mm*6mm homogeneous vinyl tile

|

Characterstics |

Standard |

Unit |

Result |

|

resistance value |

ISO 10581-EN 649 |

10^2-10^8 oum |

Safety criteria

| Flammability | GB 8624-2012 | class | Bl |

| Slip resistance | DIN 51130 | group | R9 |

| Dynamic coefficient of friction | EN 13893 | class | DS |

Formance behaviour

|

Sheet width |

ISO 24341-EN 426 |

m |

2 |

|

Sheet length |

ISO 24341-EN 426 |

m |

20 |

|

Overall thickness |

ISO 24346-EN 428 |

mm |

2.0 |

|

Total weight |

ISO 23997-EN 430 |

kg/m2kg/㎡ |

3.1 |

|

Wear resistance |

EN 649 |

group |

T |

|

Dimensional stability |

ISO 23999-EN 434 |

- |

X:<0.4% |

|

Color fastness |

ISO 105-B02 |

rating |

>6 |

|

Resistance to staining |

EN 423 |

No Stain 0 |

|

|

Bend resistance |

GB/T 11982 2-2015 |

no crack |

|

|

Antibacterial |

ISO 22196 |

Class one |

|

|

Anti iodine |

Good |

||

|

Classification |

|||

|

Domestic |

ISO 10874-EN 685 |

class |

23 heavy duty |

|

Commercial |

ISO 10874-EN 685 |

class |

34 very heavy duty |

|

Industnial |

ISO 10874-EN 685 |

class |

43 heavy duty |

Additional property

| Castor chair |

Antistatic Behavious |

| Underfloor Heating | Chemical Resistance |

Application

Anti-static floor is widely applied to electronic computer rooms, clean rooms, remote exchange rooms, manufacturing industry of electronic devices, workshops of microelectronic industry, asepsis rooms, central controlling rooms, and workshops which require purification and electronic proof. It is now widely used in banks, post offices, railway, medicine, and microelectronic industries.

600000 square meters standing stocks, 24000 square meters daily production.

Our flooring are packed carefully, to ensure the goods are delivered in good condition.

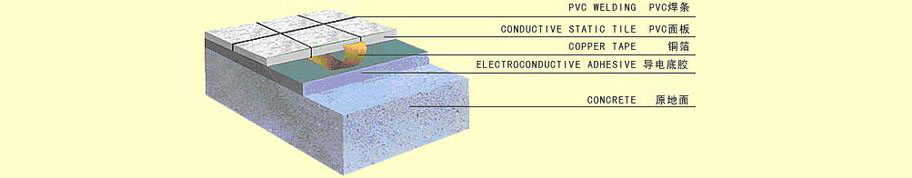

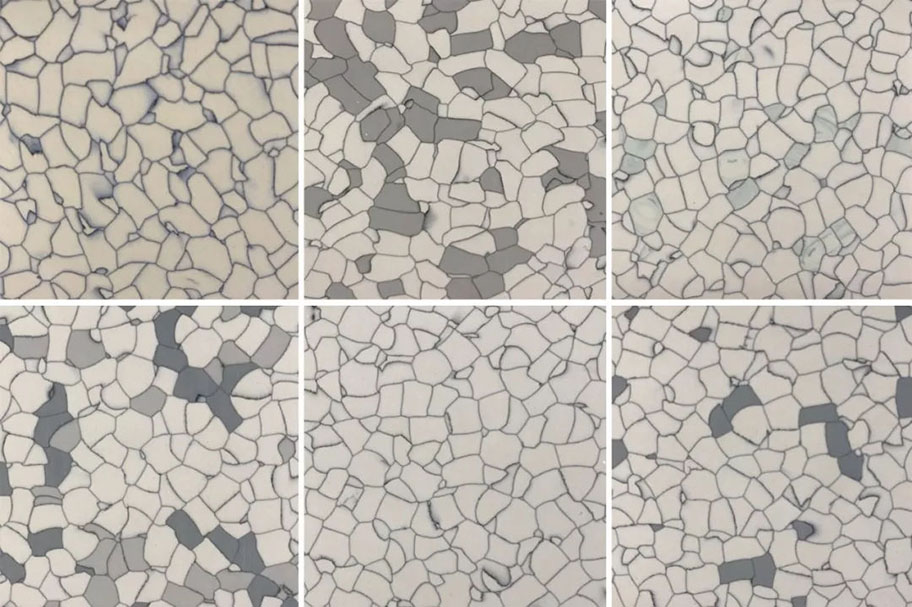

The installation

Conductive ESD floor should be installed on Sub floors that are leveled ,smooth and free of cracks ,Residual humibity should be under 2.5% tested with the CM Dumb test . Tiles,adhesive and installation site should reach a temperature of at least 18 at least 24 hours before installation.and paste the tiles with qualified conductive glue below 10 ohm for further details on installation methods.