PVC anti-static floor is to reduce the surface resistance of the ground by doping conductive materials or coating the surface with a conductive coating, so that static electricity can be effectively released and the accumulation of static electricity can be avoided. This floor is usually used in industrial places that require anti-static properties, such as electronics factories and hospital operating rooms.

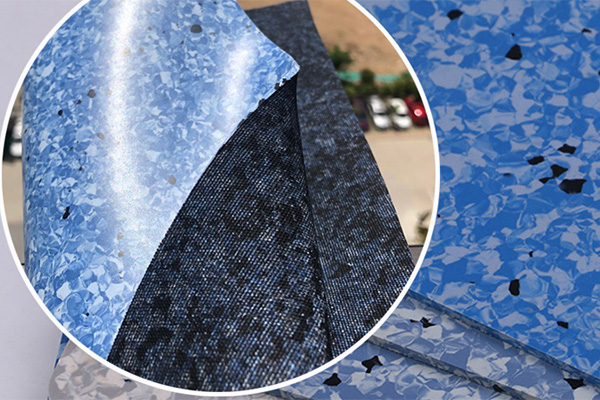

The types of PVC anti-static floor include: 1. Homogeneous conductive vinyl floor: This kind of floor has a smooth and tidy surface, rich colors, high strength, fire retardant, easy to clean and maintain, and is suitable for places that need to be kept clean and anti-static at all times. 2. Composite PVC anti-static floor: The floor is made of PVC composite material, the surface has anti-scratch, waterproof, moisture-proof and other properties, suitable for computer rooms, electronics factories, pharmaceutical factories, operating rooms, laboratories and other places. 3. PVC anti-static carpet: with comfortable foot feeling and wear resistance, the surface is not easy to leave dust and stains, easy to clean, suitable for homes, office buildings, shopping malls and other places. The above three kinds of PVC anti-static floors are floors with good anti-static performance, which can effectively prevent the generation and accumulation of static electricity.

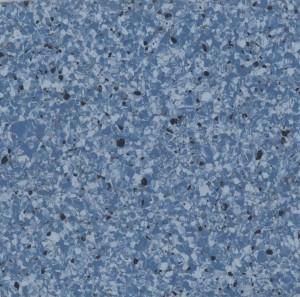

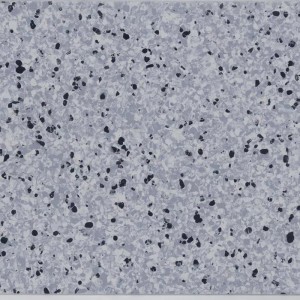

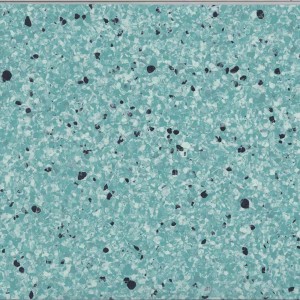

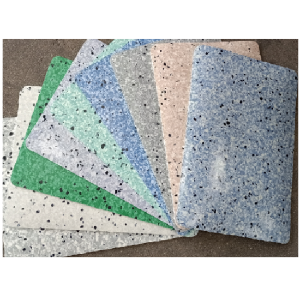

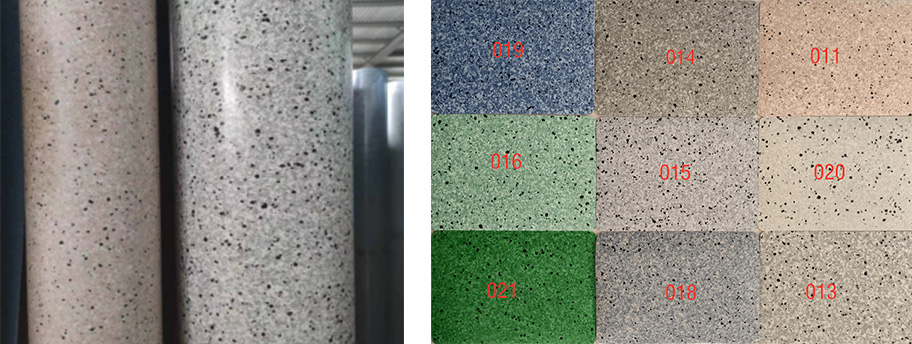

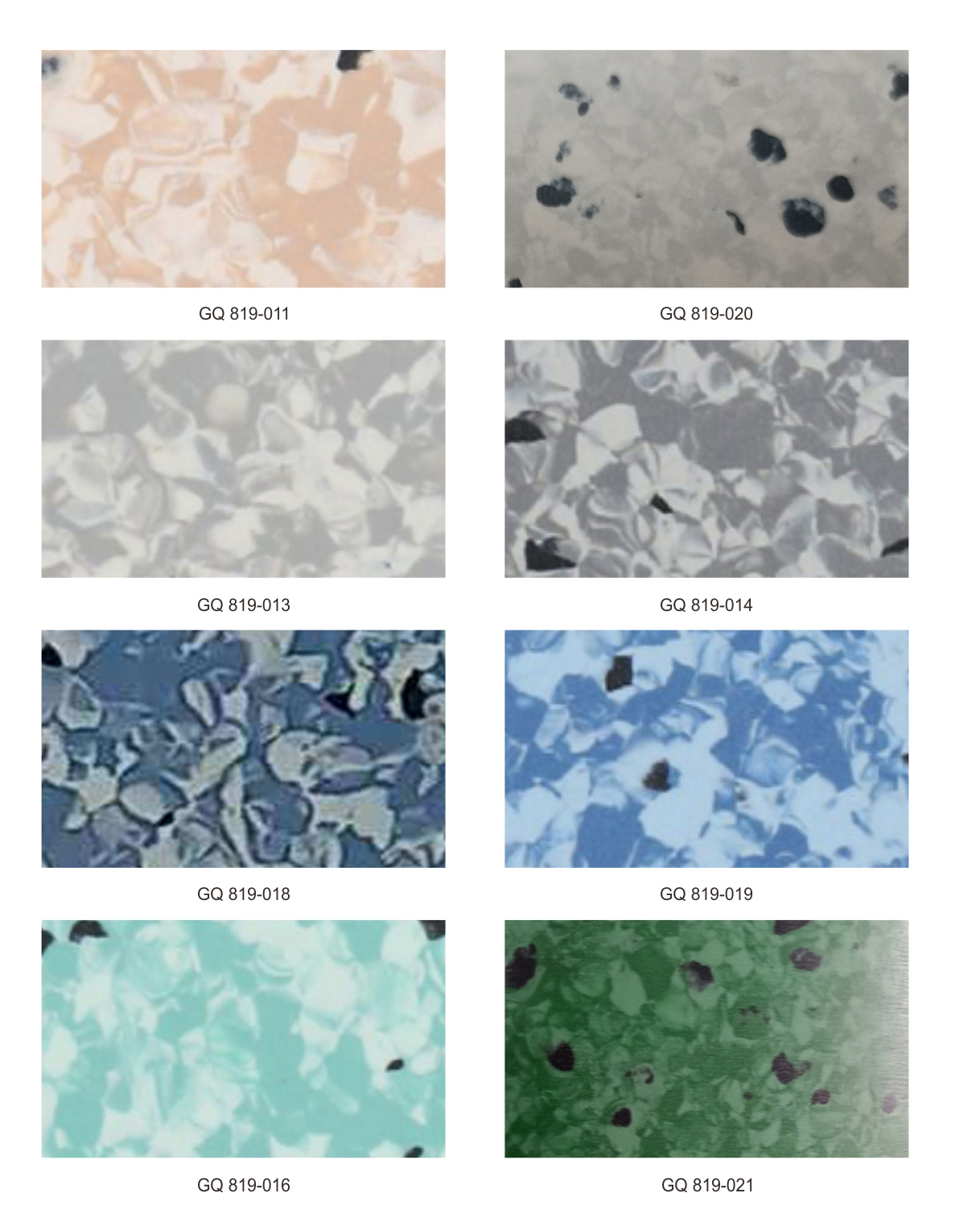

Multiply color

Application

Anti-static floor is widely applied to electronic computer rooms, clean rooms, remote exchange rooms, manufacturing industry of electronic devices, workshops of microelectronic industry, asepsis rooms, central controlling rooms, and workshops which require purification and electronic proof. It is now widely used in banks, post offices, railway, medicine, and microelectronic industries.

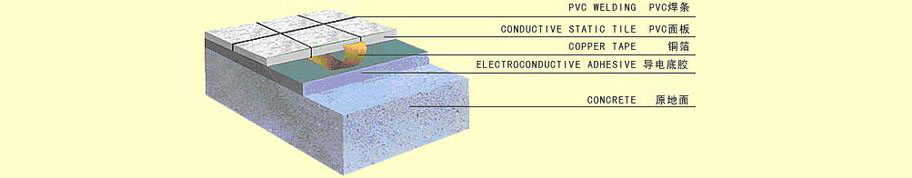

Conductive ESD floor should be installed on Sub floors that are leveled ,smooth and free of cracks ,Residual humibity should be under 2.5% tested with the CM Dumb test . Tiles,adhesive and installation site should reach a temperature of at least 18 at least 24 hours before installation.and paste the tiles with qualified conductive glue below 10 ohm for further details on installation methods.