Summary Preface:

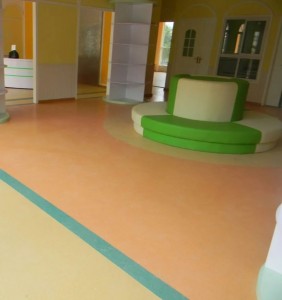

PVC flooring is widely used in hospitals, kindergartens, badminton courts and other places. As a new type of floor paving material, what issues should we pay attention to when paving it?

Self-leveling construction:

- The first step is to treat the base layer. Clean the floor that needs to be self-leveling and apply an interface agent. After applying the self-leveling interface agent once, you need to wait until it dries before applying a second time. Just apply it twice in total. After it is completely dry twice, start beating. The beating must take a long time to completely open the material.

- Grouting and scraping. If it is made on the floor, it is usually about 3 mm thick. If the ground is uneven, it can be made 5-6 mm thick.

- Defoaming treatment is mainly to eliminate bubbles on the slurry. It is best to roll it 3-5 times with a tool.

- To protect the finished product, it takes at least 24 hours after the construction is completed before people can enter it, and it will be extended to 48 hours on rainy days. If the ground foundation is good, you can ignore the self-leveling step.

Floor laying:

- Whether it is a roll or a sheet, it should be left on site for more than 24 hours to restore the memory of the material and keep the temperature consistent with the construction site. Use a special trimmer to cut and clean the burrs of the roll.

- When laying, the overlap between two pieces of material should be cut with overlap. Generally, the overlap is required to be 3 cm. Be careful to keep cutting with one knife. When laying, roll up one end of the roll. Clean the floor and the back of the membrane first, then scrape the glue onto the floor.

- After the floor is pasted, use a cork block to push the floor surface flat and squeeze out the air. Then use a 50 or 75 kg steel pressure roller to roll the floor evenly and promptly repair the warping of the splicing joints. Excess glue on the floor surface should be wiped off in time.

Wire welding:

- Grooving must be done after the glue is completely solidified. Use a special grooving tool to groove along the joints. In order to make the welding firm, the slits should not be through the bottom. It is recommended that the grooving depth be 2/3 of the floor thickness. At the ends where the seam opener cannot cut, use a manual seam opener to open seams of the same depth and width.

- Before welding, the dust and debris remaining in the groove must be removed.

- The temperature of the welding gun should be set at about 350°C. At an appropriate welding speed (to ensure that the welding rod melts), squeeze the welding rod into the opened groove at a uniform speed.

- When the welding rod is semi-cooled, use a welding rod straightener or a moon-shaped cutter to roughly cut off the part of the welding rod that is higher than the floor plane. When the welding rod is completely cooled, use a welding rod straightener or a moon-shaped cutter to cut off the remaining convex part of the welding rod.

Post time: Nov-06-2024